|

Air Film Technology

What Is Air Film Technology?

Air Film Technology is a relatively new concept developed in

Great Britain back in the 1950s which resulted in the appearance of

the Hovercraft.

Here is the fundamental concept behind air film technology.

It is the art of forcing a load away from the floor surface

harnessing the power of compressed air under control.

Here is the air film process on more detail.

Air Film is produced when a constant amount of compressed air is

distributed through a tightly-sealed component - such as an air

caster module - until it reaches what is known as an air bearing.

When the air fills the air bearing and filled the polyurethane

diaphragm of the air bearing it has nowhere else to go except to try

and exit through the exhaust holes of the air bearing.

These exhaust holes lead the compressed air directly to the floor

surface on which you are working. When the exhausted air hits the

floor surface it is instantly repelled by the floor and sent back to

where it came from. However, the exhaust chambers are now full of

incoming compressed air and therefore cannot go back.

The only place for the exhausting air to go is upwards into the

diaphragm. When the diaphragm of the air bearing cannot accept any

more incoming air the air simply forces the air bearing to raise

away from the floor surface - such is the force of the air pushing

against it. When this happens a "film of air" has been generated

between the load the air bearings are supporting and the floor

surface.

This film of air is used to easily transport (float) the load to

wherever it need to be.

Here is a typical air caster module with fitted air bearing. You can

see in the center of the black polyurethane diaphragm the four

exhaust holes that release the incoming compressed air.

Here are two examples of air caster modules: a round steel module

and a square aluminum module. The process is the same whichever load

module is used. The types of module - square or round - is to

determine the type of load which will be placed onto the air caster

modules.

When an air caster load module is manufactured, it is formed into a

load moving kit system by adding more modules to form a complete

system kit complete with all air hoses, valves and other components

required to set up the system right out of the box. The only thing

you have to supply is the compressed.

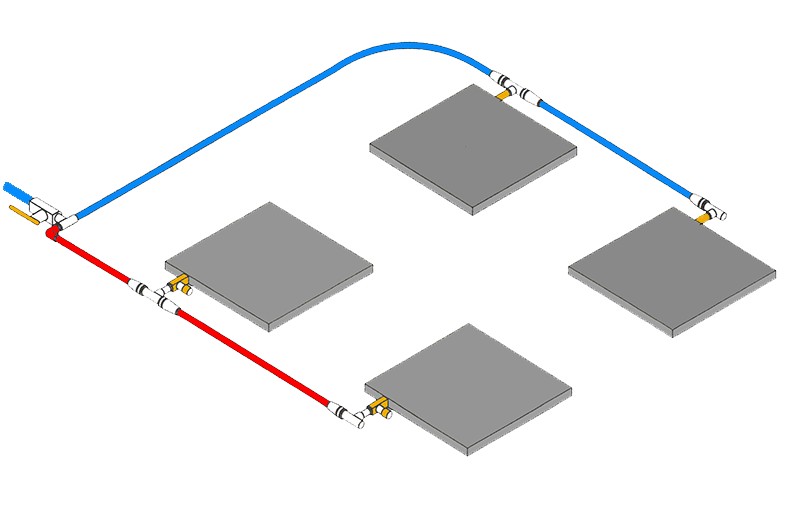

Here is a completed square aluminum four-station kit system all

ready to go and to the right is a low profile air caster kit system

laid out in a typical square profile setup.

Did you know that an air bearing and caster machine moving system will make your load

moving so much

easier, and way more cost effective?

Hovair Systems air bearing powered systems are

designed to lift and move heavy loads and machines that are too heavy

for conventional methods such as forklift trucks, overhead gantry and

crane methods.

Air powered (pneumatic) load moving systems work in a

series of four or more and lift your load away from the floor much the

same as a Hovercraft. Our products use the same principle: air film

technology.

Using our wide range of products you can now

move loads and machines of any shape, size or weight using just a little of the

regular compressed air in your shop. These systems are so easy to use. Anyone can use them: guys, gals, even the boss.

We have a great range of starter kits available

complete with all hoses and necessary fittings. When your load capacities

grow, simply add a couple more modules to take the strain and it is

business as usual.

You can move loads of up to 100 tons and more with

virtually no effort at all.

Move your loads into places that a forklift truck or

overhead crane just cannot get to. There is no limit to the tight spaces

you can maneuver into.

Check out our

main web site and look

for the demo videos which will show you just how easy these systems are

to use.

We would love to hear about your load moving need so

why not contact us to chat about those needs and whether or not we can

help you. No obligation whatsoever.

Contact Us.

Hovair Systems of Seattle are one of the leading

air bearing manufacturers, and have over 40 years experience in providing

load moving solutions to industry in USA, Canada and the rest of the

world.

Here are some of the benefits to using a Hovair

Systems air bearing and caster load moving system:

- Affordable, safe, and

cost-effective

- Uses only compressed

air in your shop - no messy fuels or nightly charging

- Can be permanently

fixed to heavy machinery for quick and easy machine moving

- Available in

lightweight aluminum or round steel formats

- Height profiles as low

as 1¼" - modules easily slide under most loads

- Terrific backup and

support service by Hovair Systems management

These great systems are in

use all across the world and are making life so much easier for their

owners. Ask Boeing, Hewlett Packard, Pilkington, Lockheed Martin - all

companies that use them daily.

Here are some links to our air powered load moving and machine handling

products:

Hovair Home Page

Hovair Products

Everything you need to know about air bearings & casters

Contact Us

Thank you for your visit

|